AWAH Z3 Safety Inspection Guide

The AWAH Z3 is an innovative electric lifting and lowering device from the AWAH brand. It operates with a power drill for lifting and a lever for lowering. Its unique dual locking system offers superior safety compared to traditional single-lock or synchronized dual-lock systems.

However, no device is immune to wear or malfunction over time. Proper operation as per the manual and regular inspections can help identify potential issues early, minimizing risks and enhancing safety.

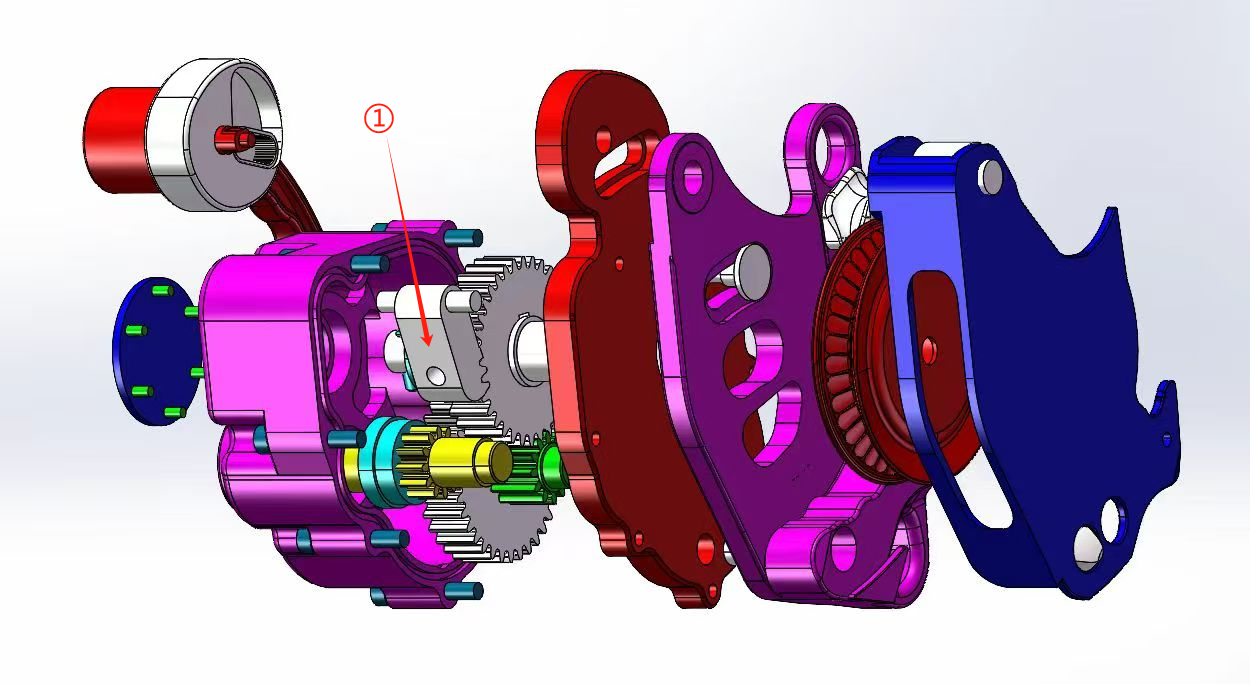

Core Mechanism

Figure 1: Ratchet Locking System

The AWAH Z3 features a two-stage safety system:

-

First Locking Stage: Ratchet Lock System

The ratchet is pressed against the gear by a spring (see Video 1) to provide initial locking. If the ratchet fails, the rope wheel will rotate backward, activating the built-in collapse self-locking system to prevent a fall. This system engages after approximately 10 cm of descent, clamping the rope to stop the fall.Advantage: During lifting, the self-locking mechanism is not under stress and thus does not wear out.

-

Comparison with Traditional Systems

- Single-Lock Systems: Rely solely on the ratchet. Failure results in a direct fall.

- Synchronized Dual-Lock Systems: Two identical ratchets wear out simultaneously, resulting in failure and potential falls.

- AWA Z3 Dual-Lock System: The self-locking mechanism only activates if the first stage fails, providing true emergency backup.

Operation Tips

Operation Tips

Correct Operation:

When stopping during lifting, ensure the gear (see Figure 1) is engaged and locked before removing the drill. Sudden drill removal may activate the self-locking system.

Important Notes:

- Self-Locking System Limitations: Once triggered, the device can safely lower the load or personnel but must be taken out of service and inspected by the manufacturer or an authorized dealer.

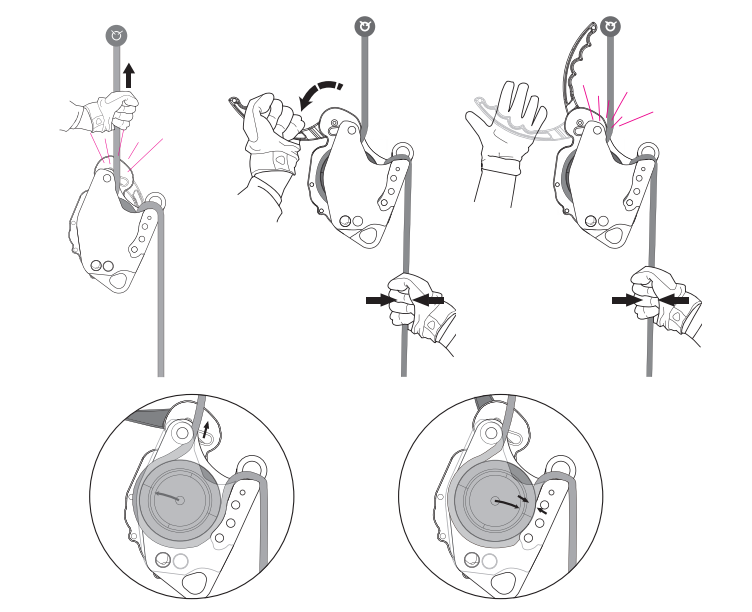

- Risk Analysis: Activation of the self-locking system may produce debris (see Figure 2). This debris can jam the mechanism or weaken the main shaft, rendering the self-locking system ineffective.

Figure 2: Condition After Activation of the Collapse Self-locking Mechanism

Inspection Checklist

| No. | Inspection Time | Normal Condition | Fault |

| 1 | Before each use |

Rotate the rope wheel counterclockwise. You should hear approximately 34 uniform clicks. | Uneven or fewer than 34 clicks indicate a ratchet fault. |

| 2 | Before each use | Rotate the rope wheel clockwise. It should lock. | If the wheel rotates slightly clockwise, the locking mechanism has failed. Do not use the device. |

| 3 | Before each use |

Shake the device laterally: you should hear a faint click from the self-locking block. Note: 1.If no sound is heard when shaking from multiple angles, turn the rope wheel by 1/4 turn and try again.

|

If no sound is heard, the self-locking block may be stuck. Device needs repair. |

| 4 | Before each use | Hinges of the gearbox and main plate should move freely without obstruction. | Blocked hinges could prevent the rope wheel from clamping the rope, risking a fall. |

Additional Checks from the Manual

The AWAH Z3 differs from traditional ascenders, descenders, or pulleys by incorporating a precision gear transmission system and dual locking mechanism. Understanding its operation and performing regular maintenance as advised by the manufacturer can extend its service life and improve safety.