AWAH Z2/Z3 Selection Guide

AWAH Z2 and Z3 are electric lifting and lowering devices under the AWAH brand. Both use a drill as their power source, but they differ significantly in their application, safety features, and rope compatibility. This guide provides a detailed comparison to help you choose the right equipment.

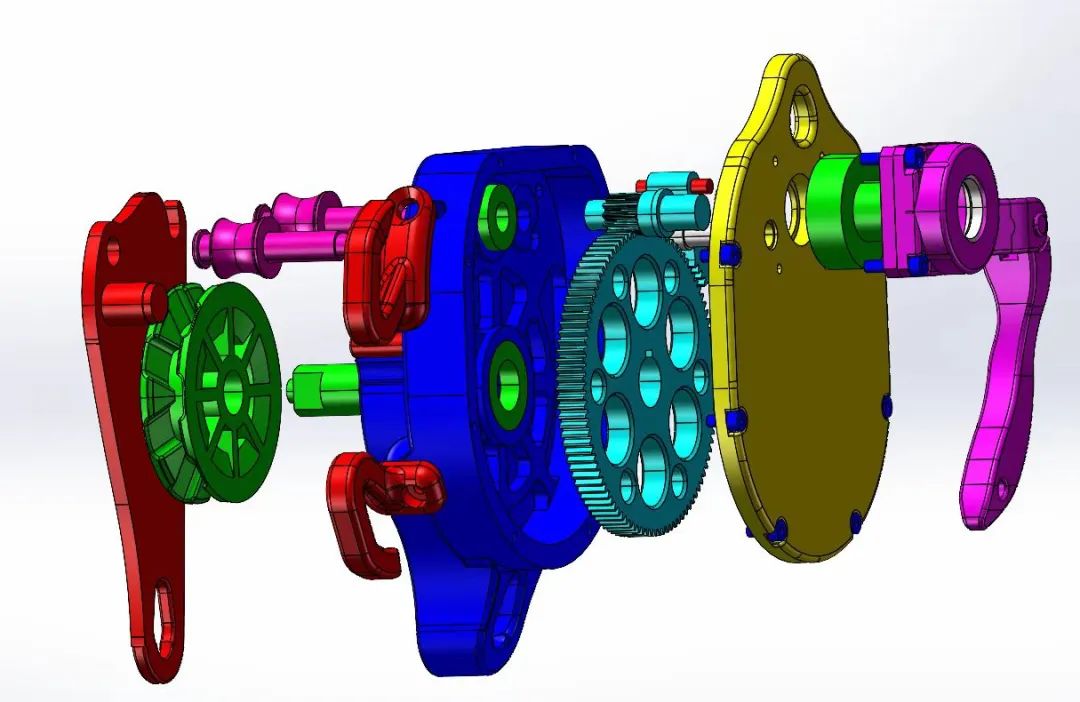

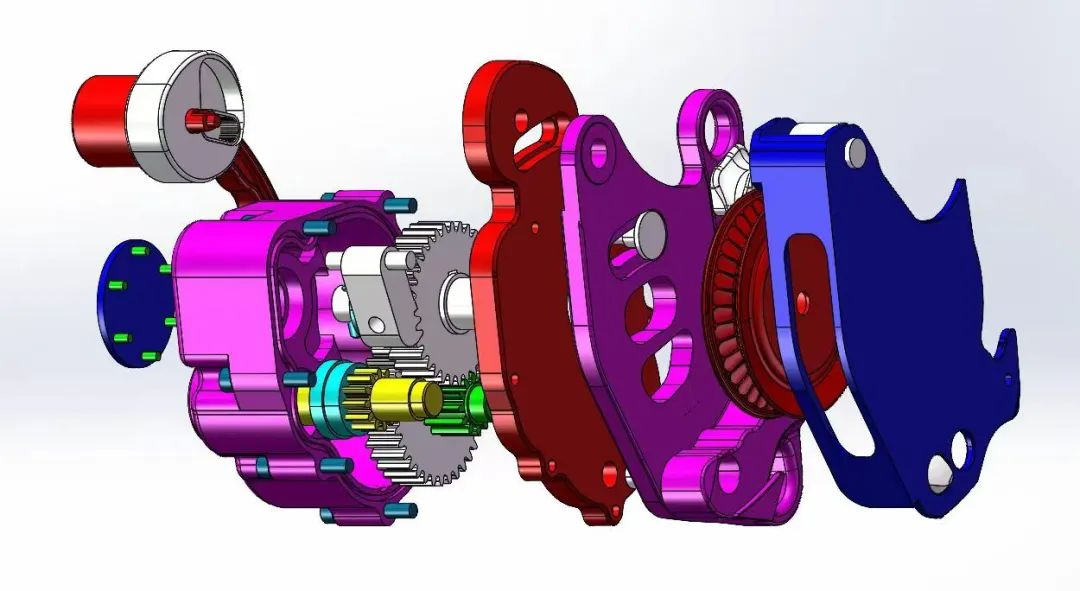

I. Structure Diagrams

AWAH Z2

AWAH Z3

II. Model Comparison

| Model Parameters | Z2-R | Z3 | Description |

| Safety | ★ Low |

High |

1. Z2 requires an external backup system. 2. Z3 has a built-in collapse self-locking mechanism. ★ Note: Dual protection is recommended. |

| Rope Pinching Risk |

★ Possible |

None |

Thin or soft ropes may get pinched in Z2's wheel but will not cause a fall. ★ Note: Pinching does not lead to a fall. |

| Lifting Slippage |

None |

Possible |

Z3's wheel is designed for both lifting and lowering, and improper weight or rope pairing may cause slippage. |

|

Locking Slippage |

None | None | Both Z2 and Z3 provide sufficient locking to prevent rope slippage. |

| Ease of Use |

Low |

High |

1. Z2 cannot be used alone and requires an external backup. 2. Z3 can be used standalone, with an integrated self-locking system. |

| Energy Efficiency | High | Low | Z3's rope clamping structure reduces energy efficiency. |

| Locking Mechanism | Ratchet |

Ratchet + Swing Block | 1. Ratchets wear over time. 2. Z3 features a dual-locking mechanism: if the ratchet fails, the backup locking system is activated. |

| Unlocking Mechanism |

Ratchet Hook | Rope Wheel Opening | 1. Z2 experiences impact during unlocking, with only two states: stopped or fully unlocked. 2. Z3 offers linear, smooth unlocking by handle angle adjustment. |

| Transmission Ratio | 8.33:1 | 8.00:1 | 1. Z3 is faster in lifting. 2. Z3 requires more powerful drills. |

| Gear Count | 2 | 4 | 1. Z2 uses counterclockwise drill rotation for input. 2. Z3 uses clockwise drill rotation for input. |

| Secondary Suspension Hole |

Available | Available | Minimum Breaking Strength (MBS) ≥ 22 kN. |

| Water and Dust Protection | None |

IP66 | 1. Z3's gearbox has IP66 water and dust protection. ★ Note: Keep the guide rollers of both Z2 and Z3 dry to prevent rust. |

| Friction Mechanism | Friction Hook | Rope Wheel Clamping | 1. Friction hooks provide good heat dissipation but may twist ropes. 2. Rope wheel clamping offers smoother lowering. |

| Rope Type | Mechanical Static Rope | EN 1891 Semi-static Rope | 1. Mechanical ropes have tightly woven cores and are more durable. 2. EN 1891 semi-static ropes are more versatile. |

| Maintenance Cost | Low |

High |

1. Z2's rope wheel has a longer lifespan, typically requiring only other parts to be replaced. 2. Z3's rope wheel has a shorter lifespan. |

| Overall Evaluation | 1. Suitable for long-distance cargo lifting. 2. Better for dirty ropes (e.g., grease, ice, silicone). |

1. Ideal for frequent switching between lifting and lowering. |

★ Note: This comparison is specific to Z2 and Z3 and does not apply universally. |

III. Product Images

AWAH Z2

AWAH Z3